頁(yè)banner/n5-14402161877.jpg)

- Service

頁(yè)banner/n5-14402161877.jpg)

Electroless plating is a process of producing a metal deposit by a controlled redox reaction under the catalysis of a metal. It is also called autocatalytic or electroless plating, and the following conditions are required for electroless plating.

1 . The potential at which the reducing agent is oxidized in the solution is significantly lower than the potential at which the metal ions are reduced, so that the metal may be deposited on the substrate.

2 . The prepared solution does not spontaneously decompose, and the metal deposition process occurs when it comes into contact with the catalytic surface.

3 . When adjusting the pH and temperature of the solution, the reduction rate of the metal can be controlled, that is, the plating speed can be adjusted.

4. The metal to be precipitated should be catalytically active and the coating can be thickened.

5. The reaction product does not interfere with the normal progress of the plating process, that is, the solution has a sufficient service life.

Compared with electroplating, electroless nickel has a uniform coating thickness, does not require a DC power supply, and can be deposited on non-conductors, but the cost is much higher than electroplated nickel, because the bath life is limited, mainly used in places where plating is not suitable, such as plastic. Metallization, treatment of aluminum (alloy), or replacement of chrome plating as a wear resistant coating.

For copper alloys and steel substrates, it is best not to use electroless nickel plating, because the plasticity and toughness of chemical nickel are much worse than that of electroplated layers, especially for deformed parts, which are both expensive and bad. It is recommended to use electroplated nickel or copper plating. nickel.

Plating features:

1. The resulting coating is a nickel-phosphorus alloy containing a certain amount of phosphorus, and its phosphorus content varies between 3% and -14% depending on the composition of the solution and the operating conditions.

2. The coating is an amorphous layered structure. When heat treatment, the layered structure gradually disappears with the crystallization of Ni3P. When the phosphorus content is higher than 8%, the coating is non-magnetic; when the phosphorus content is less than 8% The magnetic properties are also very different from the electroplated nickel layer.

3. High corrosion resistance, especially when the phosphorus content is high, is much more resistant to corrosion than electroplated nickel in many etching media. However, it should be noted that for aluminum alloy steel parts, it is not a guarantee of corrosion resistance after electroless nickel plating, because chemical nickel is still cathodic to them, as long as there are pores. Electrochemical corrosion.

4 . The hardness is high. The microhardness of this coating is about 500-600Hk. After heat treatment at 400°C, its hardness can reach 1000Hk, which can be used to replace hard chrome.

1.plate liquid decomposition

When the chemistry plates a Nie liquid to resolve, can seeing arriving not only plate there is reaction on the piece, and many under the Xi amount of more normal circumstance of bubble in the middle of plating to also have reaction inside the liquid, plating a liquid, take out a little amount of plate the liquid is placed to in the graduated cylinder can see suspend of the solid grain appear.At this time, should immediately stop Shi Du, take out spare parts to place in cold water, plate the liquid has been filtered machine. take out a person inside the back up slot, adjust to plate a liquid set for cent and pH, use 30%~50% nitric acids clean to plate slot.After finishing backing the Nie layer of slot wall, will used for the nitric acid aqua that backs a Nie layer to move to go into another a back up slot, treat next time back a Nie layer again use.Flush to plate slot with tap water and pure water immediately after.The end will plate a liquid to use to filter machine to take out a person to plate slot again, after heating into 85 ℃ Shi Du.If plate a liquid to still resolve a phenomenon at this time, then should just the right amount add a stabilizing agent again, and lower pH.

The spare parts surface oxidizes skin and hair to stab more, had better carry on spraying a sand processing.The car should keep a ground moist and keep dust from raising when plates.Plate slot the top should add a cover to reduce the humidity solid grains, such as evaporation and dust...etc. to fall into to plate a liquid as far as possible in.

The pH that plates a liquid adjusts not appropriate, result in to plate liquid decomposition to is disaster usually.This because alkaline pH adjustment over join quickly, make to once plate the partial pH of the liquid high, creation Xu-like in shape Ni(OH):, Provided to in great quantities have the solid surface of catalyst function, under the dual function of the heat and the high pH, make to plate the liquid produce a great deal of diameter within few minutes is only one μ m~black particle of Nie Lin of 3 μ ms.These particle area quality than reach to 0.the 028 ms 2/g~0.the 76 ms 2/g, the composition is 10% for Nie 85%~90% and Lin~l 5% and impurities l%~2%, the thus big surface accumulates further promote to plate a liquid of decomposition, cause to plate liquid expiration.So, don't adjust pH when plates.

At plate liquid occurrence decomposition, have to adopt urgent measure to plating to join ice acetic acid in the liquid, make pH descend to 3.5 following, will plate a liquid to use to filter machine to take out again into back up slot(or directly the percolation is in the middle of plating slot) adjustment, can immediately resume.Joining the sparse sulfuric acid can also attain to repress the function of plating the liquid decomposition, but will result in the density increment of sodium sulfate.The acetic acid sodium that joins an ice acetic acid creation is the good buffer that plates a liquid, and allows scope bigger.

2.plate a liquid poisoned

The chemistry plates"poisoned" performance of liquid for plate the Xi hydrogen on the piece to measure more normal circumstance under have to be little, the deposition speed that plates a layer is very slow, sometimes even stop deposition after the spare parts gets into to plate a liquid for several minutes, this is mainly what stabilizing agent and some impurities too much result in.When the stabilizing agent slightly too many, is a cathode the spare parts, the stainless steel is an anode, with flow density 0.the 6 As/dm 2~1 As/dm 2 electrolysis few minutes, can immediately resume as usual.When the stabilizing agent content leads abashed, have to leave part to plate a liquid, again join to lately plate a liquid.

3.plate the 1 F top hemp to order and pinhole

Plating a surface status is poor, machine impurities, oxidize all of not yet finisheds like skin,etc in addition to is clean and adjust to plate liquid pH and plate unsteady etc. of liquids to all probably make to plate the 1 F creation hemp to order with pinhole while carrying on chemistry to plate.Should lower the roughness of zero Ci surfaces as far as possible, the radicle body surface is shining more, then chemistry's plating more a Nie layer is shining, the pinhole that plates a layer is more little.The pH that doesn't want to adjust to plate a liquid when plates, plating the liquid should circulate percolation, can also add just the right amount of stabilizing agent.Plate in the chemistry Nie in put more important surface of spare parts with a downward exposure or become 900 capes with level possibly.

4.plate the 1 F thickness asymmetry

Because each surface of spare parts and horizontal plane clip Cape different, the chemistry plates ejecting of hydrogen the speed is also different.The hydrogen that the spare parts up produces can quickly leave, but get down of the superficially output hydrogen then want to follow surface to rise to an edge to leave and reduced thus the noodles with plate actual contact time of liquid, resulted in to plate 1 F thickness not and all of phenomenon.When spare parts surface and horizontal plane become to look like perpendicular, because of hydrogen follow spare parts surface ascension, will also result in the upper part plate a layer is more slightly thin than lower part.In addition, the parts that eject smoothly in all hindrance hydrogens all probably make the plating of part's layer thinner and the surface pinhole is more many.For size bigger spare parts, should make to move, and want to make to plate a liquid to be placed in to flow status on the lower hem during Shi Du as far as possible, with benefit at the ejecting of hydrogen.

5.plate the 1 F surface flower spot

The some factory contains the chrome metal alloy steel spare parts adoption chemistry to after plating the Nie plate 1 F the surface is even and shining, combine dint good, can satisfy to compare the work environment request that the Ke engraves.But appeared chemistry to plate the phenomenon of Nie layer surface a great deal of"flower spot"(the external appearance is more difficult to see).The normal chemistry plates a Nie layer the surface is even and shining, the naked eye could not observe a little bit dark.But break down?Plate 1 F the surface present "flower spot" form, the part has dark color grain or spot piece-like in shape deposition thing, position uncertain and shape anomaly, fluid-like in shape Be distributed to plate a Nie layer of surface.

Should plate layer and radicle body to combine well, but the surface is rough, using the decuple magnifier observation should plate a layer, there is roe of fish-like in shape globosity thing piling up together, present the color that a dark Nie plates a layer.(polishing with the cloth round is shining)Adopt a gold mutually the microscope(40000%) observe normal chemistry and plate Nie layer and breakdown and plate a Nie layer and discover, plate Nie layer surface as usual, basically is a small globosity body along with whet a scar direction even pile up a growth, form some one direction of afterbirth-like in shape body piece, accidentally have several globosities bodies that grows up bulge at even superficial, even the small ball folds together;But break down plate Nie layer surface, the small globosity body covers full whet scar place, have of can see whet a scar direction of growth, but greatly parts of areas are together globosities thing to bulge a growth(perpendicularity in plate the 1 F surface direction), intensively take to connect, have already bulged feeling, the external appearance coarseness has no light, forms non- light gathering balls and there is the breakdown surfaces of holes.

Contrast analysis the detection isn't the reason that the chemistry plates a liquid to go to ion water, but plated a surface to glue to attach some organic"impurities", cleaned not clean, changed the form that the spare parts surface Ni-P metal alloy plates a layer to check to grow behavior thus, formed "flower spot" of this kind of asymmetry to plate a layer.Adopt a washing dissimilarity clearly of afterwards strengthened to clean, plate the 1 F surface"flower spot" before plating of phenomenon cancellation, resumed even and shining surface external appearance.

1.Introduction

In recent years, with the rapid development of the electroplating industry and the gradual transformation of people's aesthetic views, in addition to the functional coatings of special needs, more and more decorative electroplating has been widely welcomed by the society [1]. The pearl nickel plating has a satin-like luster, giving a soft and comfortable feeling. It feels smooth, elegant and feminine, like a pearl surface, and is very popular among people [2]. The pearlescent nickel plating has a slightly lustrous color and a soft color to avoid eye fatigue. Therefore, it is widely used, such as mobile phone casings, camera casings, handicrafts, interior decoration parts, household appliances, decorative parts, auto parts, and clock accessories. Kitchen utensils and eye frames. Electroplating decorative chrome, bright silver or bright gold on pearl nickel plating to form sand chrome, sand gold or sand silver can meet different hobbies and needs of people. In addition, the pearl nickel satin coating has fine structure, low porosity, low internal stress, good corrosion resistance, and excellent resistance to scratch and scratch resistance. It has become an important protective decorative coating in Europe and the United States.

In the early 1960s, Europe, the United States, and Japan successively published literature and patents on pearl nickel plating processes and equipment, and various additives developed have also been commercialized. In the late 1980s, China began experimenting and researching in this area. There were few literatures and patents. In particular, the research on additives was basically at the stage of exploration. Most of the products in the production were purchased from foreign companies.

This paper introduces the preparation method of pearl nickel coating and the action mechanism of additives in the process of forming satin gloss coating, and reviews the development status of pearl nickel plating at home and abroad.

2.Preparation method and principle of pearl nickel plating

The method for producing the surface of the pearl nickel includes a mechanical method and an electroplating method, and the electroplating method can be further divided into a composite plating method and an emulsifier method.

The mechanical method is to sandblast or blast the substrate to form an uneven surface, and then perform electroplating. The pearl-like satin effect prepared by this method is relatively good, but has the disadvantages of high scrap rate, poor working environment, and high labor intensity, and has been basically eliminated.

The composite plating method is to add non-conductive particles to the base plating solution, and the particles are uniformly dispersed in the plating solution under strong stirring, and co-deposited with nickel, and the particles are embedded in the plating layer to form a nickel composite plating layer [3]. However, due to the pearl-like satin effect and softness of the composite coating is not very satisfactory, it has been basically eliminated.

The emulsifier method is currently the most common method for preparing pearl nickel plating, and it is also the most active research direction. The organic surfactant added to the plating solution can form an emulsion in the plating solution under suitable process conditions, so that the small emulsion droplets are uniformly dispersed in the plating solution. Under the action of the electric field, the positively charged small emulsion droplet moves toward the cathode and is adsorbed at the cathode. The adsorption site is shielded by the droplets of the emulsion, and the metal cannot be deposited, so that the portion forms a recess. The adsorption and desorption processes of the droplets on the surface of the cathode are alternately alternated, and the electrodeposition of the metal on the surface of the electrode is also alternately performed, resulting in the formation of numerous overlapping circular pockets on the surface of the coating layer, according to which The average diameter is different for pearlescent coatings with different effects.

1. What is pearl nickel?

Pearl nickel, also known as satin nickel, satin nickel, is a decorative coating. The appearance is milky white, with a satin-like luster, giving a soft and comfortable feel. It feels smooth and smooth like a pearl surface.

The matte color of the pearl nickel coating is slightly lustrous and the color is soft, which can avoid eye fatigue. Therefore, it is widely used, such as mobile phone casings, handicrafts, auto parts, clock accessories and eyeglass frames.

Pearl-plated nickel workpiece

Pearl-plated nickel workpiece

Figure 2. Pearl nickel surface observed with a (x100) magnifying glass

2. Preparation of pearl nickel by emulsifier method

The emulsifier method is currently the most common method for preparing pearl nickel, and it is also the most active research direction.

Nickel-based nickel plating solution (Watt nickel: NiSO4 as the main salt, NiCl2 can increase the conductivity and promote the dissolution of the anode nickel plate, boric acid is the pH buffer)

The organic surfactant added to the plating solution forms an emulsion in the plating solution at a certain temperature. The small emulsion is dispersed in the plating solution under agitation. Part of the adsorption at the cathode, the adsorption site is shielded by the emulsion, and the metal cannot be deposited, so that a portion is formed in the cavity. The adsorption and desorption of small droplets on the surface of the cathode are alternated, and the electrodeposition of the metal on the surface of the electrode is also alternated, resulting in the formation of numerous overlapping circular pockets on the surface of the coating, according to which The average diameter is different for pearlescent coatings with different effects.

1. Methyl orange (pH=3.1-4.4): 0.1 g of methyl orange is dissolved in 100 ml of hot water. If there is insoluble matter, it should be filtered.

2. Methyl red (pH=4.4-6.2): 0.1 g of methyl red is dissolved in 60 ml of ethanol, dissolved and diluted with water to 100 ml.

3. Phenolphthalein (pH=8.3-10): 1 g of phenolphthalein is dissolved in 80 ml of ethanol, dissolved and diluted with water to 100 ml.

4. Thymolol (thymolphthalein) PH = 9.3-10.5: 0.1 g of thymol phenol is dissolved in 100 ml of ethanol.

5, bromocresol green (also known as bromocresol blue) PH = 3.6-5.2: 0.1 g of bromocresol green dissolved in 2.88 ml of 0.05 mol / L sodium hydroxide solution, diluted with water to 250 ml.

6. Potassium chromate indicator solution: Take 10 g of potassium chromate and add 100 ml of water to dissolve.

7. Chrome black T (or chrome black 6B): 0.5 g of chrome black T (or chrome black 6B) plus 50 g of sodium chloride is ground uniformly.

8. Ammonium urate: 2 g of ammonium urate (murexide) and 100 g of sodium chloride were ground and mixed uniformly.

9. PH=10 buffer solution: Dissolve 54 g of ammonium chloride in water and add 350 ml of ammonia water (relative density 0.89), and dilute to 1 liter with water.

10. PAN indicator [1-(2-pyridylazo)-2-naphthol]: 0.2 g of PAN was weighed and dissolved in 100 ml of ethanol.

2, 11, 7, 0.5g / L starch indicator how to prepare?

Weigh 0.5g of soluble starch into a 50mL beaker, measure 100mL of distilled water, first adjust the starch to a paste with a few drops, then take about 90mL of water in the electric furnace to heat to the slightly boiling, pour the paste starch, then use Rinse the 50 mL beaker 3 times with the remaining distilled water, pour the washing liquid into the beaker, then add 1 drop of 10% hydrochloric acid, and boil for 3 minutes. Stir in the heating process, cool, and add a few drops of chloroform (carbon trichloride). Note: Adding chloroform is to prevent the starch solution from deteriorating too quickly or without adding chloroform, but the starch indicator is usually replaced once a week.

12. BCP indicator: Weigh 0.1 g of bromocresol purple in 20 ml of ethanol, add water to 100 ml after stirring.

13, thymol phthalate indicator solution: Take thymol phenolphthalate 0.1g, add 100ml of ethanol to dissolve, that is. The color change range is pH 9.3 to 10.5 g (colorless → blue). Thymol blue indicator solution Take 0.1 g of thymol blue, add 4.3 ml of 0.05 mol/L sodium hydroxide solution to dissolve, and dilute to 200 ml with water. Color change range pH 1.2 ~ 2.8 (red → yellow): pH 8.0 ~ 9.6 (yellow → purple blue).

14, litmus indicator: Preparation method: Take 1g of litmus powder dissolved in 50mL of water, let stand for a day and night after filtration. Add 30 mL of 95% ethanol to the filtrate and dilute to 100 mL with water. The color change range is pH 4.5 to 8.0 (red → blue).

The company is the most famous surface treatment expert in China. The company is based in Guangdong, and its products are sold to the Pearl River Delta, Yangtze River Delta, Fujian, Shandong, Sichuan and other places, and exported to Vietnam, Malaysia, India and other places. Is one of the most important suppliers in the market today

Dyeing series products, widely used in lighting, bathroom, furniture, locks, handicrafts, electronics, electrical appliances, etc., can produce antique oxidation on steel, copper, zinc, tin, silver, aluminum and various metal, plating parts and other metal surfaces. Floor. It is a pioneer in the industry and completely replaces similar imported products. The company has strong technical strength and has a group of senior researchers and experienced experts and experienced engineers on site.

Commonly used metal surface coloring methods, including chemical coloring and electrolytic coloring.

Chemical coloring, mainly by the adsorption of the surface of the oxide film, the dye or colored particles are adsorbed in the voids of the film layer, or the metal surface is reacted with the solution to form colored particles and deposited on the metal surface, so that the metal exhibits the desired color. This type of technology has low requirements on equipment, simple operation, no power consumption, and low cost.

Metal coloring is the primary purpose of chemically coating the surface of a colored film of a particular medium to be decorative and preserved. The coloring of the metal forms an oxide film of a certain color in the aqueous solution. The metal dyeing process is to first form an oxide film with a certain porosity on the metal surface, so that the oxide film interacts with the oxidant in the dyeing solution to make the metal surface exhibit the desired color.

Coffee copper

This agent is specially designed for the surface coloring of copper, electroplated copper and copper alloy. Divided into multiple models, can be different brown (according to customer needs, provide appropriate potions and adjust accordingly). This product is easy to use, does not need to add any equipment, normal temperature operation, recycling, imported raw material quality is stable, widely used in lighting, furniture, plumbing, zipper, handicrafts and other industries.

High temperature copper

Alkaline blackening solution, suitable for electroplating of red copper and high content of copper alloy. It can form a black and bright copper oxide film on the surface of the workpiece. The blackness of the film exceeds the acidic black film layer, and the film has good adhesion, no ash, and is wear-resistant. It has a wide working range, especially at lower levels. Applicable at the temperature.

Familiar problem | Abnormality analytical | Solution |

Not enough black | It's low to dye a slot density | Raise to dye slot to dye a proportion |

It's low to dye slot temperature | Raise to dye slot temperature appropriately | |

Dye time shortage | The extension dyes time | |

Apply color not and all | Activate shortage | Strengthen to activate sour wash |

Sour copper light too high | Strengthen to activate sour wash, raise to dye a slot temperature, density | |

Not enough bright | The temperature leads Gao | Adjust temperature appropriately |

The density leads Gao | Lower to dye a slot density appropriately | |

It's too long to dye slot to use a period | Filter a slot liquid and replace parts of slot liquids |

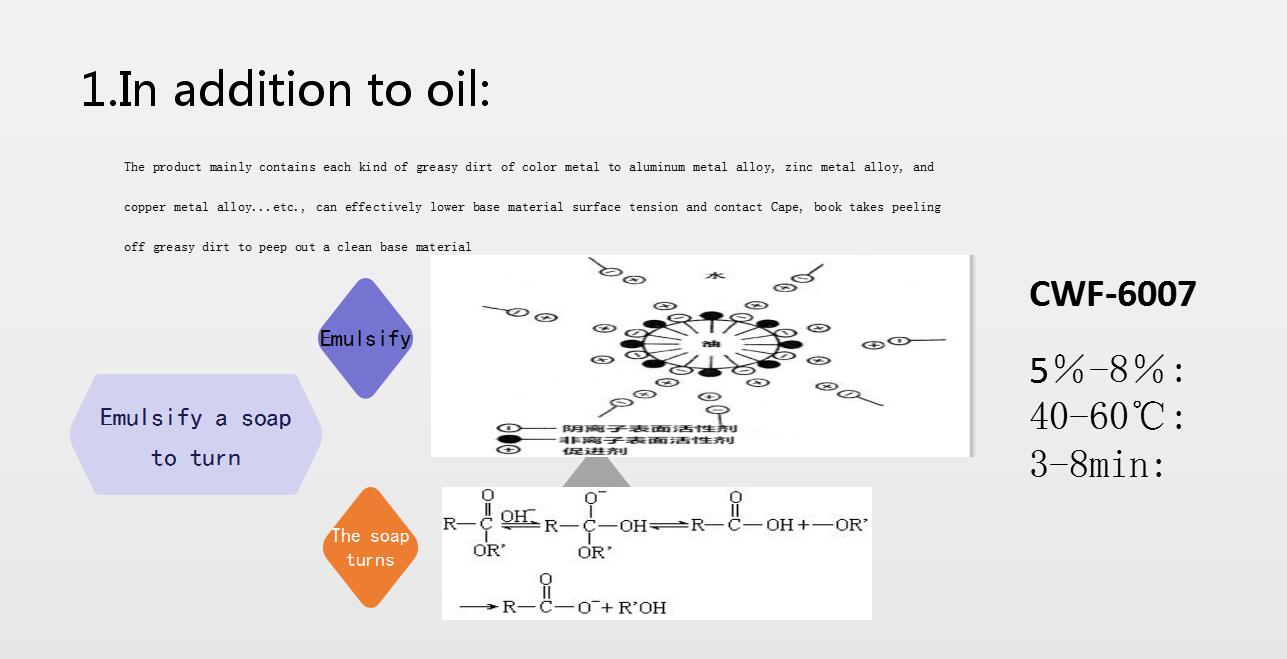

Chemical degreasing is a process of removing oil from the surface of a part by using a hot alkaline solution to saponify and emulsify the oil. The alkaline solution includes two parts: one part is a basic substance such as sodium hydroxide, sodium carbonate, etc.; the other part is a surface active substance such as sodium silicate or an emulsifier. The saponification of the alkaline substance removes the saponifiable oil, and the emulsification of the surfactant removes the unsaponifiable oil. Chemical degreasing has the characteristics of simple process, easy operation, low cost, non-toxic oil removal and non-flammability. However, the commonly used alkaline chemical degreasing process has a weak emulsifying ability. Therefore, when the surface oil is mainly mineral oil, or when the surface of the part is excessively attached with butter, paint or even colloidal substances, before chemical degreasing, Removal by mechanical means or organic solvent, this process must not be neglected in the production of chemical degreasing is mainly used for pre-de-oiling, and then electrochemical degreasing to completely remove the grease.

(1) Principle of chemical degreasing

1) Saponification

The saponification reaction is a process in which a saponified oil chemically reacts with a basic substance in a degreasing liquid to form soap and glycerin. When the oily product is placed in the alkaline degreasing solution, the oil stain is removed due to the above saponification reaction. The composition of a general animal and vegetable oil can be represented by the formula (RCOO) 3C3H5 wherein R is a higher fatty acid hydrocarbon group containing from 17 to 22 carbon atoms. The chemical reaction of oil and fat in hot alkali is (RCOO)3C3H5+3NaOH→3RCOONa+C3H5(OH)3. If R=17, it is sodium stearate (soap), sodium stearate can be dissolved in water, A surfactant that promotes the dissolution of fats and oils.

2) Emulsification

Mineral oils or other non-saponifiable oils cannot be saponified with an alkali, but they can be emulsified by the action of a surfactant to form an emulsion to be removed. Emulsification is a process in which one of two mutually incompatible liquid solutions is dispersed in another liquid to form an emulsion. The surface active material having an emulsification function is called an emulsifier. Anionic or nonionic surfactants such as sodium silicate, sodium stearate, OP emulsifier, and the like can be used in chemical degreasing. In the degreasing process, first, the emulsifier is adsorbed on the interface between the oil and the solution, wherein the lipophilic group has an affinity with the oil on the surface of the part; and the hydrophilic group is affinity with the degreasing aqueous solution. Under the action of the emulsifier, the adhesion of the oil stain to the surface of the part is gradually weakened. Under the combined action of the fluid dynamic factors, the oil stain gradually detaches from the surface of the metal part, and the fine droplets are dispersed in the degreasing liquid to become opaque. Liquid, to remove the oil on the surface of the part. Heating and stirring the degreasing solution will accelerate the oil into the solution, thus increasing the speed of degreasing and improving the degreasing effect. Therefore, in chemical degreasing, higher temperature and agitation measures are generally used, and ultrasonic waves can be used to accelerate the removal. Oil process.

(2) Chemical degreasing liquid composition and process conditions

The main components of the chemical degreasing liquid include alkali or basic salts such as sodium hydroxide, sodium carbonate, sodium phosphate, sodium pyrophosphate, sodium silicate, sodium borate, and, in addition, metal chelators such as EDTA and sodium citrate. Organic additives such as various emulsifiers. Usually, the alkaline degreasing liquid contains two or more kinds of alkali or basic salts. Sodium hydroxide and sodium carbonate are two inexpensive, strong alkaline materials. Phosphate such as sodium phosphate and sodium pyrophosphate is the source of alkali, and it acts as a metal ion to chelate calcium, magnesium and other softened hard water, and buffers the pH value of the solution. The colloidal film formed by silicate can protect the two sides of aluminum and zinc. The metal is not corroded. The organic additive acts to assist in emulsifying and dispersing the oil.

The formulation of the chemical degreasing fluid is selected according to the different properties of the matrix material and the requirements for degreasing.

Paint stripping principle: The paint stripper contains a special active substance. When the paint stripper penetrates into the gap of the polymer segment of the coating polymer, it causes the polymer to swell. The volume of the coating film is continuously increased to generate internal stress, which weakens and destroys the adhesion of the coating to the substrate. The coating film swells from a spot to a sheet to swell, causing the coating film to wrinkle. Finally, the coating film is completely separated from the substrate.

According to the risk of a little bit in common use chemicalses, the big body can is divided into easy Ran and easily explode with poisonous 3 typeses and summarize as follows now:

(A)Easy Ran chemicals

Combustible air:The hydrogen, B An and chlorine B alkane, ethylene, coal gas, hydrogen, oxygen, hydrogen sulfide, methane, chlorine methane,

Easy Ran liquid:Gasoline, the B ether, acetaldehyde and carbon disulfide, petroleum ether and benzene, methyl benzene and xylene, acetone and acetic acid B vinegar, methyl alcohol, and ether...etc..

Easy Ran solid:Red Lin and three vulcanizations two Lins, Mao, , aluminum powder etc..The yellow phosphorus is ability from the Ran solid.

Can see from the top, big part of organic melting agent, all is combustible quality, such as use or maintain not appropriate, very easily arouse to burn trouble, so need special attention, relevant regulation, the this book laboratory generally safe knowledge is part of and relevant the chapter have been already described.

(Two)Easy explosion chemicals

The reaction velocity of air mixture with composition but difference, when the reaction velocity attains certain limit, will arouse an explosion.The B ether that usually uses, not only it fume ability and air or oxygen mix and form to explode mixture and place Chen Jiu's B ether be oxidized born of lead oxide will also arouse an explosion while distiling.In addition four hydrogen Mao Nan ethers will as well arouse an explosion because of once producing oxide.Is some with the higher speed carries on of put hot reaction, because a great deal of born air will also arouse explosion and accompany with to take place to burn.

Generally say to come, the explosive substance quality mostly implies following structure or organic functions regiment:

Ozone, lead oxide

Chloric acid salt, Gao chloric acid salt

The chloride of nitrogen

Second nitric radicle compound

Heavy nitrogen and fold a nitrification thing

Thunder sour salt

Nitric radicle compound(TNT, picric acid salt)

B Gui compound(B Gui metal salt)

Explode by oneself of have:Gao chloric acid according to, nitric acid according to, thick Gao chloric acid, thunder sour mercury, and TNT...etc..

Hybrid the occurrence explode of have:

(1)Gao chloric acid+ether or other organic matters;

(2)Gao potassium manganate+glycerin or other organic matters;

(3)Gao potassium manganate+sulfuric acid or sulphur;

(4)Nitric acid+magnesium or iodine turn hydrogen;

(5)The nitric acid presses+vinegar or other organic matters;

(6)The nitric acid presses+zinc powder+water;

(7)Nitrate+chlorination second tin;

(8)Lead oxide+aluminum+water;

(9)Sulphur+oxidize mercury;

(10)Metal sodium or potassium+water.

Oxide and organic matter contact very easily arouse an explosion.While using thick nitric acid, Gao chloric acid and leading to oxidize hydrogen...etc., have to specially notice.

Prevent°from exploding in addition to this book front part has been already described of knowledge, have to also notice the following what time:

(1)The experiment that carries on a possible explosion, have to in the special design of flameproof the deep-fried place carry on;The use may have when the chemistry of explosion try have to work well personal protection, need to be worn mask or protection glasses, at not the broken glass carry on an operation in the well ventilated Chu;Combine to try to reduce drugs dosage or density, carry on little or the half is little by little on trial.To the experiment that doesn't understand function, absolutely not to the gist.

(2)The picric acid beard keeps in the water, some have to fill with water conservancy over the oxide(such as lead oxidize benzene A Mao).

(3)The easy explosion remnant has to carefully handle, get not arbitrarily throw indiscriminately.

(Three)Poisonous chemicals

The chemicals that we get in touch with everyday has plenty of a deadly poison thing, have to be very careful while using;Have of try over a long period of time contact or get in touch with excessive, will also arouse acute or chronic poisoned, influence health.But as long as control the rule and protection measure of using the poison, then can avoid or reduce the poisoned opportunity to the lowest degree, and start to develop to presume the cultivated manners and courage of using the poison.

The poisonous chemicals is usually invaded a human body by following path:

(1)The breath way invades.So the poisonous experiment has to carry on in the well ventilated Chu, and usually notice indoor air flowing freely.

(2)The skin glues a film irruptive.The cornea of eyes to chemicals very sensitive, so start experiment, have to wear protection glasses;While starting experiment an operation attention don't make to try to get in touch with skin directly, hand or skin have wound more the beard is special caution.

(3)The digest way invades.This circumstances are few, in bar of poisoned, any drugs can not be used a people's gustation and strictly forbid in the laboratory to take a meal, have to wash hands after testing to end.

(4)Strictly forbid to take out a poison laboratory.

Poisonous chemicals is as follows:

1.poisonous air:Bromine, chlorine, fluorine and cyanotype the hydrogen is sour, the fluorine turn hydrogen, bromine to turn the hydrogen, hydrogen chloride and sulphur dioxide, hydrogen sulfide and light spirit, ammonia, and carbon monoxide...etc. all for suffocate sex or have stimulating air.While using above air or carrying on the experiment that produces above air, have to carry on in the well ventilated well ventilated Chu, and try to absorb poisonous air, reduce pollution of the environment.If meet in great quantities harmful air Yi to the indoor, should immediately close air occurrence device and quickly stop an experiment and close fire source, the power and leave the spot.

If the occurrence hurts trouble, should see a circumstance to put paid to in time.

2.strong sour and strong alkali:The nitric acid, sulfuric acid, hydrochloric acid and hydrogen oxidizes sodium, hydrogen to oxidize potassium etc. to all stimulate a skin, has already decayed a function and results in chemistry's burning.Inhale a strong sour smoke, stimulate a breath way, use should doubly careful, and the strictly by rule operation carry on.

3.inorganic chemistry drugs

Cyanide and cyanotype hydrogen are sour:The toxicity is the strongest, to poison the function is the quickest, the cyaniding hydrogen content reaches thousand times in the air of three, in few minutes then to the person die and use the beard specially notice.The cyanide has to seal completely conservancy, have to strictly get to use to maintain system, have to wear mouth-muffle, protection glasses and gloves while taking to use, can not carry on the experiment that uses cyanide while there being wound on the hand;Have to grind a body with the cover while grinding up cyanide, carry on in the well ventilated Chu;(do not take out breeze)The instrument, table's top once using all must tidy up in person and hurtle with water clean;Hand and face should as well cautiously wash;The experiment takes a possible pollution, have to change to wash in time.Mercury:Can evaporate under the indoor temperature, the toxicity is the strongest, can cause impatient or chronic poisoned.It's well ventilated to have to notice the indoor while using;Lifting is pure or handles, have to carry on in the well ventilated Chu;If sprinkle to turn over, can pump a decompression collections with water, possibly collect completely.The tiny particle that can not collect can use sulphur powder, zinc powder or three chlorination iron aqua clearances.

Bromine:The liquid bromine can burn to the skin, the fume stimulates a mucosa, even can make eyes become blind.Have to carry on in the well ventilated Chu while applying;The glass bottle of the prosperous bromine the beard is airtight to fill to put at metal behind of in the bottle, secure knock down or tip over for depositing, so as not to;If sprinkle to turn over or break, should immediately cover up with the sand;If the skin burn immediately washes with the sparse ether or a great deal of glycerin massage, then is with the boric acid Vaseline.

Metal sodium, potassium:Meet water namely the occurrence burn explosion, while using beard caution.The sodium, potassium should keep in liquid paraffin wax or the kerosene and pack into iron bottle to cover well, put in the dry place.

4.organic chemistry drugs

Organic melting agent:The organic melting agent is respectively a lipid-soluble liquid, have already stimulated a function to the skin mucosa, have the selectivity incitement the function to the nervous system.Is like benzene, not only stimulate a skin, easily arouse unprogressive eczema, have serious damage towards building blood system and central nervous system system all.It is specially harmful to see nerve such as the methyl alcohol again.Had better replace carbon disulfide, benzene and stew an alkane with the lower petroleum ether, ether and acetone, methyl benzene and xylene of toxicity under the sistuation that the condition admits.

Sulfuric acid two AN esters:Absorbing person and skin to absorb all can be poisoned, and there is incubation period and feel after being poisoned breath way bright pain, influence the central nervous system greatly, the drop can arouse on the skin bad dead, ulcerate, resume slowly.

Fragrant nitric radicle compound:The nitric radicle that compound contains many toxicities are big, increase a chlorine atom in the compound in the nitric radicle, will as well increase a toxicity more more.The characteristics of this kind of compound is to be quickly absorbed by the skin, poisoned behind arouse bigotry anemic and Huang Ju Bing, sting arouse a skin to arouse eczema.

Benzene Fen:Can burn a skin, arouse bad dead or skin burning, should immediately wash with the wet water and sparse ether after tainting with.

Alkaloid:Majority of strong toxicities, the skin may also absorbs, the jot can cause dangerous poisoned even death.

Carcinogen:A lot of alkyls turn and absorb over a long period of time the body contains cancer-causing function, should to the attention.Include sulfuric acid among them two AN esters, to methyl benzene Huang sour AN ester, N-A radicle-N-second nitric radicle Mao vegetable, second nitric radicle two AN Ans and side nitrogen B alkane and some C Xis sour vinegar etc..Some fragrant Ans, because of in the liver through metabolism but born N-Qian radicle compound but have a cancer-causing function, include among them 2-B Mao ammonia radicle Wu, 4-B Mao ammonia radicle biphenyl, 2-B Mao ammonia radicle benzene Fen, 2- Mao An and 4-2 AN ammonia radicles accidentally nitrogen benzene etc..Part of dense wreath fragrant hydrocarbon compound, such as 3,4-the benzene combine Mao, 1,2,5,6-2 benzenes combine Mao and 9-and 10-A radicle-1,2-benzene combine Mao the etc. is all carcinogen, but 9,10-2 A radicles-1,2-benzene combine the Mao then belong to a strong carcinogen.

Have to be careful while using poisonous drugs, understand its property and operation method.Don't be stained with a dirty skin and inhale fume and splash an entrance in.Had better operate in the well ventilated Chu, wear protection glasses and gloves when it's necessary, carefully open bottle stopper, so as not to is damaged to spread.

The instrument that made to once use should hurtle to clean in person, the remnant waste casts away inside the discard urn.Usually keeping laboratory and set noodles clean and neat is also the important measure that avoids taking place trouble.The experiment has to develop a habit of washing hands after ending.Put on a few grease on the hand, keep skin lubrication, have much of an advantage towards protecting a skin also.

First, the application of anodizing process products

Anodizing products are mainly used in: mobile phones, computers, automobiles, toys and other components.→

Second, the characteristics of anodizing products.

1, lightweight and durable

2, good weather resistance

3, can be dyed with beautiful decorative effect

4, the anode film can be used as a coating base

5, high wear resistance

6, with high resistance value

Third, the anodizing process

Degreasing → alkali bite →neutralization →Chemical polishing→neutralization→anode→Table adjustment →dyeing→Sealing hole→Ash removal →Dry

1, skim:

Function: remove oil stain on the surface of the workpiece

Company products: CWF-6007

Operating conditions: concentration: 5%-8%

Temperature: 50±5

Time: 3-8min

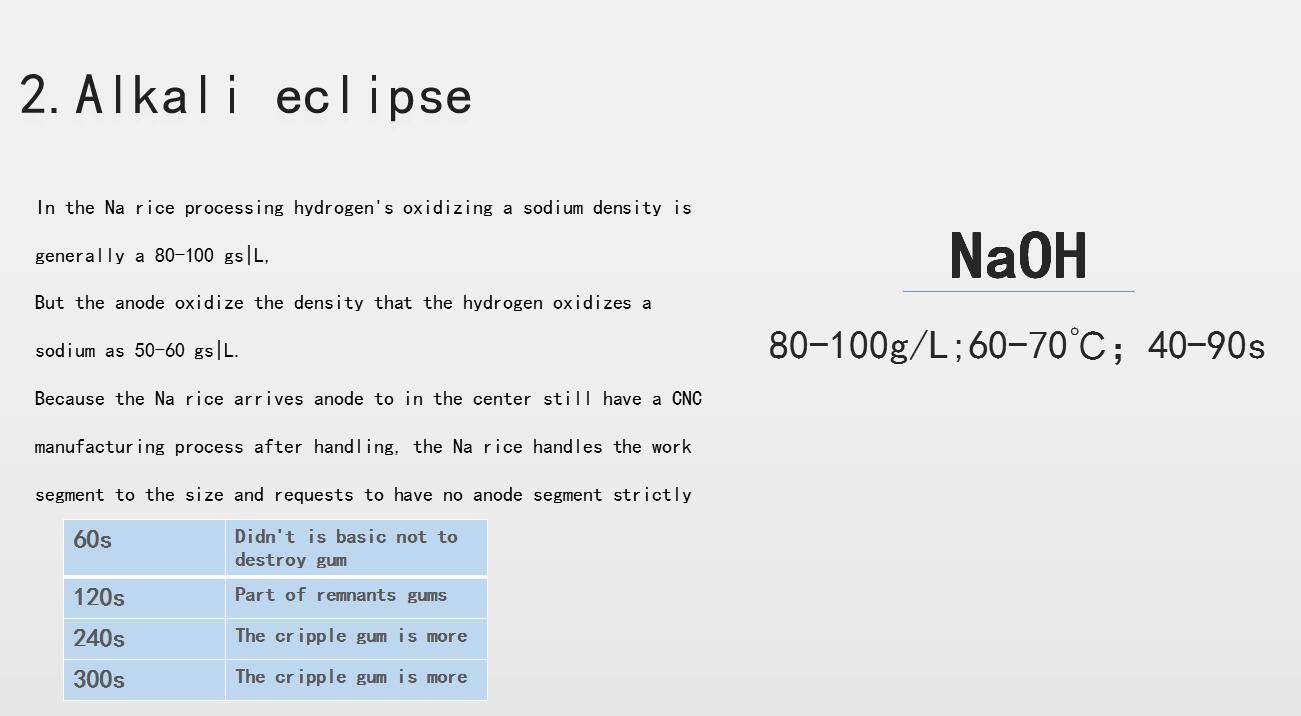

2, alkali etching:

Role: remove the oxide layer on the surface of the workpiece

Operating conditions: NaOH concentration: 45-55g / L

Temperature: 45-55 ° C

Time: 10-60 seconds

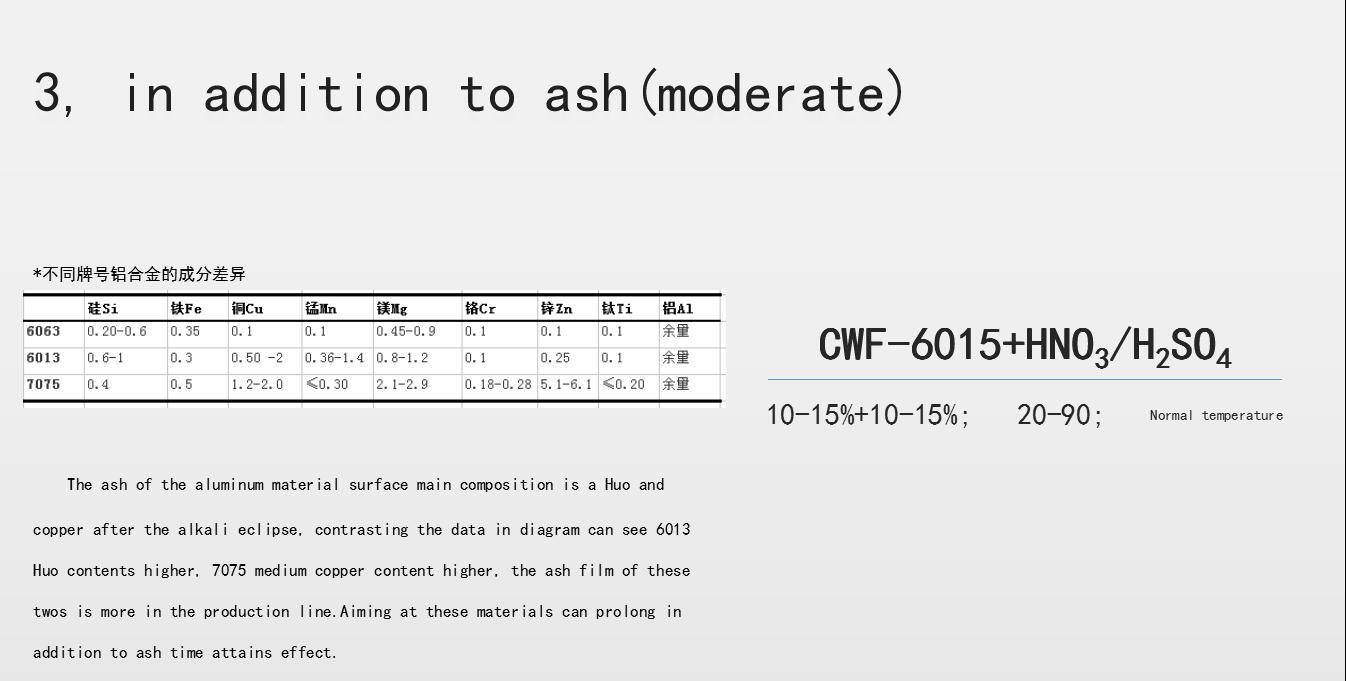

3. Ash removal:

Role: remove the black film on the surface of the workpiece to expose the pure metal substrate

Company products: CWF-6015. or CWF-6016B (cast aluminum)

Operating conditions: CWF-6015: 10%-15% CWF-6016B: 90%

Nitric acid: 10%-15% Nitric acid: 10%

Temperature: RT Temperature: 20-35 °C

Time: 30-120 seconds Time: 30-120 seconds

4. chemical throw:

Role: chemical polishing of the surface of the workpiece, increasing the gloss and thus determining the gloss after the anode

Company products: 203 systemized parabolic additives

122 system polishing additive

5. Ash removal:

Role: remove the black film on the surface of the workpiece to expose the pure metal substrate

Company products: CWF-6015. or CWF-6016B (cast aluminum)

Operating conditions: CWF-6015: 10%-15% CWF-6016B: 90%

Nitric acid: 10%-15% Nitric acid: 10%

Temperature: RT Temperature: 20-35 °C

Time: 30-120 seconds Time: 30-120 seconds

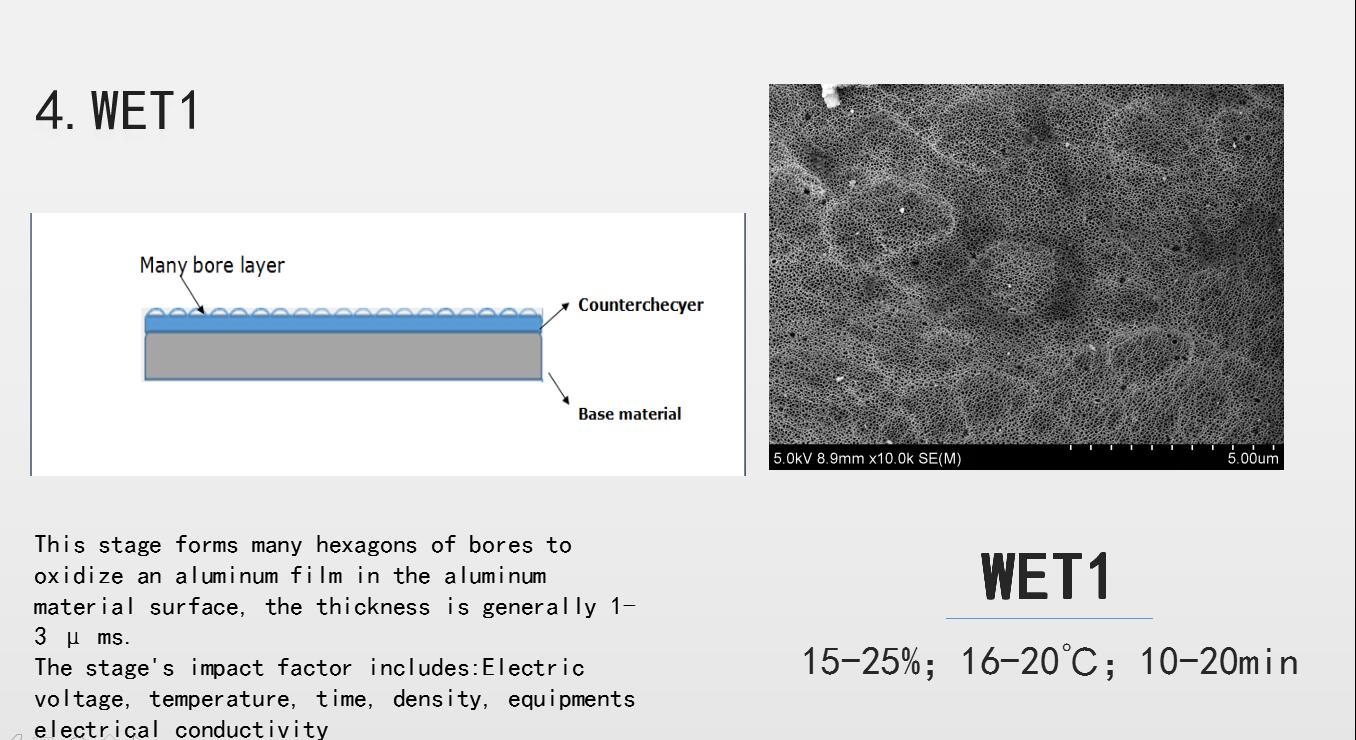

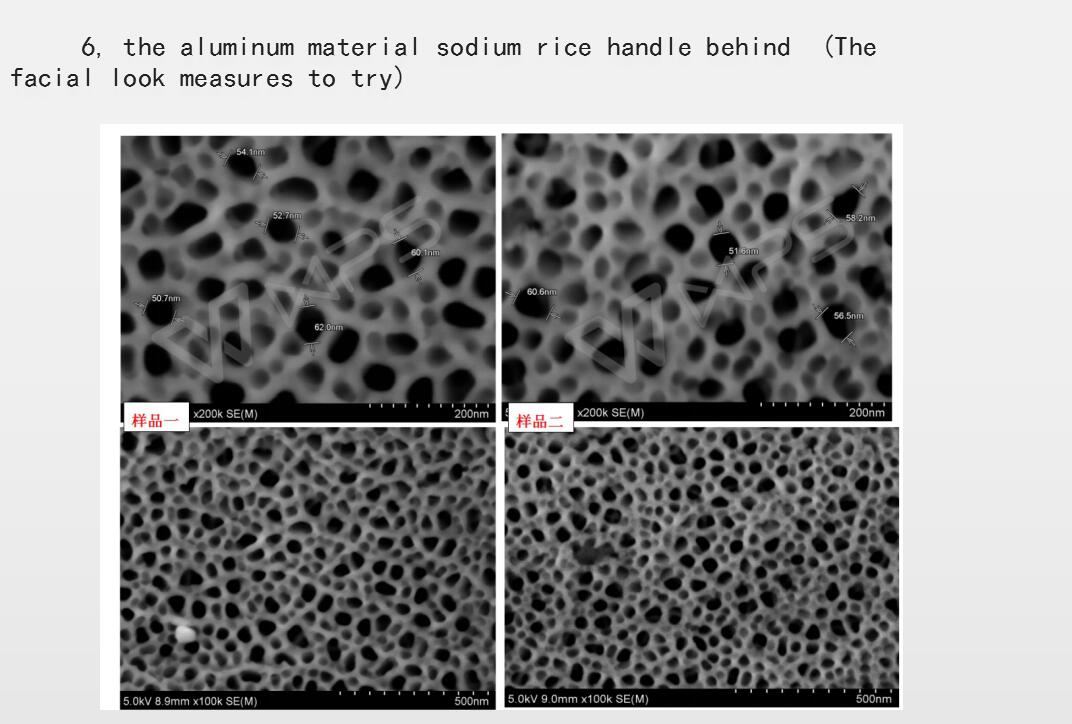

6.anode:

Function: The surface of the workpiece is converted into a layer of aluminum oxide film by the principle of water electrolysis.

Operating conditions: H2SO4: 190-210g/L

Temperature: 19-21 ° C

Time: 30-60min

One positive voltage: 10-16V

Second Yang voltage: 8-10V

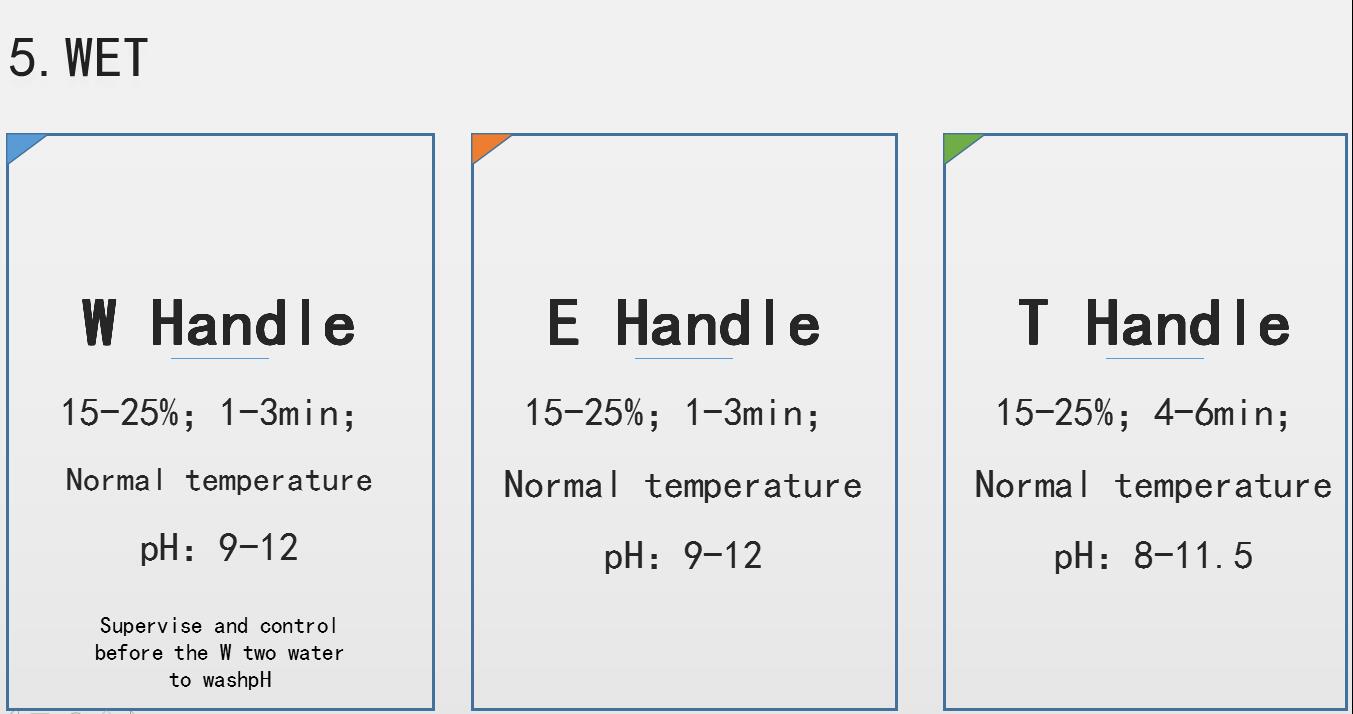

7.the table:

Function: Remove the acid from the workpiece and increase the activity of the membrane pores, which is more conducive to dyeing.

Company products: CW-42

Operating conditions:

Concentration: 40-60g/L

Temperature: 25-45 °C

Time : 3-5min X 2-3 times

8.dyeing:

Function: According to customer requirements, produce brilliance and bright colors

Operating parameters: Dyestuff: 0.2-1.0g/L

Temperature: RT-45 °C

Time: 3-5min

9.sealing:

Function: 1. The dye is enclosed in an oxide film.

2. Prevent the appearance of the anodized film from being damaged.

3. Improve the wear resistance of the oxide film.

4. The fading of the dyed oxide film is minimized, and the insulating property of the oxide film is improved.

Company products: CWF-7110

Operating conditions: concentration: 8-12g / L

Temperature: 90-95 °C

Time: 30-60min

10.Remove ash after sealing:

Function: Remove the floating ash from the sealing.

Company Products: CWF-6025

Operating conditions:

Concentration: 50-100g/L

Time: 6-10min

Temperature: 75-85 °C

Stretching oil: The metal stretching oil is made of high-quality mineral base oil and compounded with high-performance vulcanized lard and sulfurized fatty acid ester as the main agent.

Drawing oil: drawing oil is roughly classified---emulsified, semi-synthetic, synthetic,

Emulsifying type: The emulsified oil in the traditional sense is composed of a base oil, an emulsifier, a rust preventive, a lubricant, etc., and the emulsion is white.

Semi-synthetic type: a large amount of emulsifier, a small amount of base oil, coupling agent, functional additive, and the emulsion is transparent or nearly transparent.

Synthetic type: No oil, all water-soluble functional additives, color, blue, green and yellow due to the addition of dyes, and the aqueous solution is transparent.

Stamping oil: The main component of the stamping oil used in general industry is the product in the petroleum distillation reaction process (such as heavy petroleum brain), which belongs to organic matter.

Cutting oil: It is synthesized from base oil with different proportions of vulcanized lard, sulfurized fatty acid ester, extreme pressure wear-resistant additive, lubricant, anti-rust agent, anti-mold fungicide, refrigerant and other additives.

Fine grinding liquid: water-soluble polymer surfactant and composite organic borate, added with lubricating agent antibacterial agent and other additives.

Cutting fluid: water-soluble polymer surfactant and composite organic borate, added with lubricating agent antibacterial agent and other additives.

Each type of cutting fluid contains various additives besides the base oil: rust inhibitors, non-ferrous metal corrosion passivators, defoamers, and the like.

Contact Us

Fax: 0755-81448867 E-mail: hwlin_@163.com

Address: 14th Floor, Building B, Dongfang Yujing Building, Songyu Road, Songgang Town, Bao'an District, Shenzhen

National free service hotline

Copyright Dongguan Huizeling Chemical Technology Co., Ltd., 粵ICP備16104500號(hào)-1